Our focus is on the fabrication of thermoplastic structural foams by foam injection moulding. That includes the whole chain of production, the material development, appropriate injection moulds and processing techniques, as well as special processes if necessary.

Next to different injection moulding machines and injection molds, for the fabrication of structural foams from thermoplastic materials, we also have special processes on hand, for optimizing the surface quality and increasing the density reduction. Moreover, we offer extensive possibilities for analyzing and mechanically testing of such foam structures.

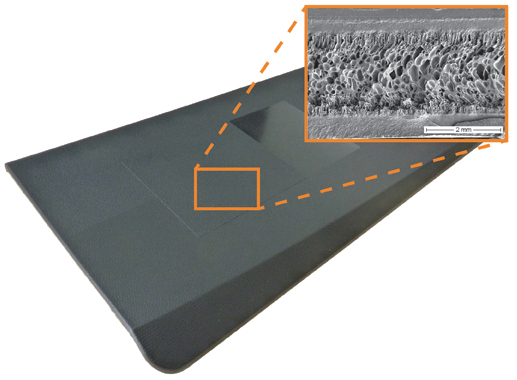

Structural foams are cellular materials with a compact outer skin and a porous core. The core density decreases continuously towards the center of the part. This integral structure is the result of the processing control during fabrication and has a similar formation mechanism for reactive systems (e.g. polyurethane) as well as for foam injection molding of thermoplastics. Due to the temperature gradient along the cross sections of the moulded part, the compact skin is formed at the cold mold wall, while the inner and warmer material can expand and become cellular.

The sandwich-like structure of injection molded integral foams offers a great potential for lightweight construction. The mass distribution in hard integral foams, such as foams of PP, PA and PC/ABS, gives very good bending properties. That is because the outer compact material can withstand high surface tensions. The reduced density of the core decreases the over all weight, which results in high weight specific flexural stiffness. This lightweight potential can be improved further, with the utilization of fiber reinforced materials and special processing technologies, which allow high density reductions in the core. Soft integral foams made out of foamed thermoplastic elastomers can be used in a two-component foam injection molding process to fabricate so-called soft touch components. Varying the integral foam structure by adapting the foaming process enables the adjustment of the surface flexibility.

Service Portfolio:

- Material and process development for the fabrication of injection molded structural foams

- Analysis of the foam structure and mechanical characterization

- Mold validations of foam injection molds

- Optimization of foam injection molding processes, regarding surface quality and potential in lightweight construction through special processing methods